GYTC8S Outdoor Armoured Cable Steel Wire Self Supporting

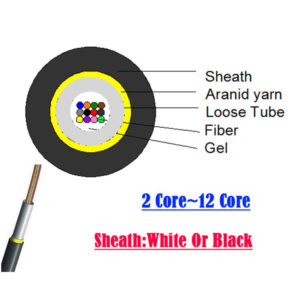

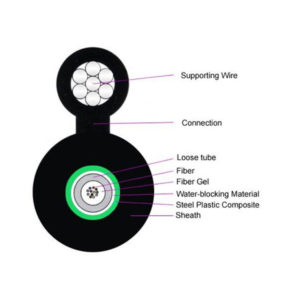

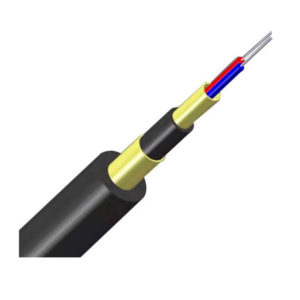

The structure of the GYTC8S cable is to insert a single-mode or multi-mode fiber into a loose tube made of a high modulus polyester material filled with a waterproof compound. The center of the core is a metal reinforcing core. The loose tube (and the filling rope) is twisted around the center reinforcing core into a compact circular core. The gap in the core is filled with water-blocking filler, plastic coated steel strip (PSP). After vertical packing, the steel wire strands are integrated into a figure-eight polyethylene sheath to form a cable. This product is used for self-supporting overhead laying.

GYTC8S Outdoor Armoured Cable Steel Wire Self Supporting

GYTC8S Outdoor Fiber Optic Armoured Cable Steel Wire Self-supporting Telecom dedicated overhead cable

Product description:

The structure of the GYTC8S cable is to insert a single-mode or multi-mode fiber into a loose tube made of a high modulus polyester material filled with a waterproof compound. The center of the core is a metal reinforcing core. The loose tube (and the filling rope) is twisted around the center reinforcing core into a compact circular core. The gap in the core is filled with water-blocking filler, plastic coated steel strip (PSP). After vertical packing, the steel wire strands are integrated into a figure-eight polyethylene sheath to form a cable. This product is used for self-supporting overhead laying.

Features:

1.Precise control of the excess length of the fiber ensures that the cable has good tensile properties and temperature characteristics;

2.The loose tube material itself has good hydrolysis resistance and high strength;

3.The tube is filled with a special grease to critically protect the fiber;

4.Polyethylene (PE) jackets have good UV radiation resistance.

The following measures are taken to ensure the waterproof performance of the cable:

1- Single wire center reinforcement core

2- The loose tube is filled with special waterproof compound

3- complete core filling

4- Plastic coated steel strip (PSP) against lateral pressure

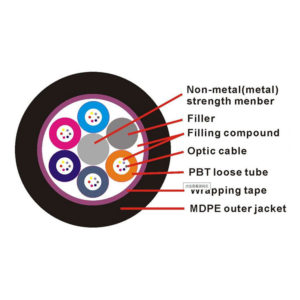

Cable design:

- 12/24/48/96 SM-fibers.

- G652D operating wavelength at 1260~1625nm.

- FRP(PE coated) as central strength member.

- Loose buffer tubes SZ-stranded.

- The buffered tube filled with filling compound while the stranded core covered with water blocking tape.

- Aramid yarns and aluminum tape armored.

- PE Cable Outer sheath and messenger wires combined.

- Suitable as: Aerial installation.

Reference Standard

IEC 60793-1, 60793-2, 60794-1

ITU-T G650, G652

Optical and mechanical characteristics of fiber

| MFD(1310nm) | 9.2mm±0.4mm |

| MFD(1550nm) | 10.4mm±0.8mm |

| Cladding diameter | 125mm±1.0mm |

| Fiber diameter | 250 ± 15 mm (Colored) |

| Cladding non circularity | £1.0% |

| Cut off wavelength | £1260nm |

| Attenuation coefficient | 1310nm: £0.35dB/km |

| 1550nm: £0.215dB/km | |

| Bending-loss performance of optical fiber | £0.05dB |

| Polarization mode dispersion | £0.1ps/Ökm |

| Zero-dispersion wavelength | 1300 – 1324 nm |

| Zero-dispersion slope | £0.092ps/(nm2•km) |

Mechanical requirements and methods of fiber cable

| Tensile strength | 2850N, conform to IEC 794-1-E1 while fiber strain is ≤0.33% |

| Crush | 2200N/100mm, conform to IEC 794-1-E3 |

| Impact | conform to IEC 794-1-E4 |

| Repeated bending | conform to IEC 794-1-E6 |

| Temperature cycling test | conform to IEC 794-1-F1 |

Fiber color coding

Each fiber will be identifiable throughout the length of the cable in accordance with the following color sequence. Fiber color in each tube starts from No. 1 Blue.

| Fiber color code | 1 | 2 | 3 | 4 | 5 | 6 |

| Blue | Orange | Green | Brown | Slate | White | |

| 7 | 8 | 9 | 10 | 11 | 12 | |

| Red | Black | Yellow | Violet | Rose | Aqua |

Tube color coding Product Structure Diagram

The loose tubes will be identifiable in accordance with the following color sequence, and each tube with 12 fibers. If there are fillers, the color is natural.

| Fiber color code | 1 | 2 | 3 | 4 | 5 | 6 |

| Blue | Orange | Green | Brown | Slate | White | |

| 7 | 8 | 9 | 10 | 11 | 12 | |

| Red | Black | Yellow | Violet | Rose | Aqua |